-

PRODUCTS

- Pharmaceutical Intermediates

- Antispasticity Agents

- Anesthetics

- Anti-Addiction Agents

- CNS Agents

- Genetic/Enzyme Disorder

- Analgesics

- Anti-inflammatory Agents

- Dermatological Agents

- Anxiolytics

- Antiparkinson Agents

- Antipsychotics

- Antidementia Agents

- Antiparasitics

- Genitourinary Agents

- Antigout Agents

- Electrolytes

- Sleep Disorder Agents

- Antidepressants

- Gastrointestinal Agents

- Antibacterials

- Blood Products

- Anticonvulsants

- Blood Glucose Regulators

-

Cardiovascular Agents

- Clevidipine Butyrate

- Choline Fenofibrate

- Binodenoson

- Bempedoic acid

- Avanafil

- Arbutamine

- Allisartan Isoproxil

- Vardenafil

- Udenafil

- Satavaptan

- Tecadenoson

- Silodosin

- Sacubitril

- Pratosartan

- Oxodipine

- Otenzepad

- Palonidipine

- Omapatrilat

- Moexipril

- Lixivaptan

- Lemildipine

- Landiolol

- Finerenone

- Dofetilide

- Darodipine

- Respiratory Tract

- Antivirals

-

Antineoplastics

- Cositecan

- Canfosfamide

- Cabozantinib

- Buparlisib

- Bropirimine

- Bosutinib

- Binimetinib

- BAL-101553

- AT-7519

- ASLAN-002

- Arzoxifene

- Apaziquone

- Apalutamide

- Anastrozole

- Amifostine

- Aldoxorubicin

- Afatinib

- Acadesine

- ZSTK-474

- Zoptarelin Doxorubicin

- Zibotentan

- Vosaroxin

- Volitinib

- Venetoclax

- Vadimezan

- Upamostat

- Tyroserleutide

- Tirabrutinib

- Tazemetostat

- Taselisib

- Talazoparib

- Taladegib

- Talabostat

- Talaporfin

- Sorafenib

- Tacedinaline

- Sonidegib

- Semaxanib

- Selinexor

- Sapacitabine

- Seliciclib

- Rociletinib

- Riviciclib

- Rimiducid

- Ribociclib

- Ralimetinib

- Quizartinib

- Prinomastat

- Pimasertib

- Phenoxodiol

- PD-0325901

- Orantinib

- Ombrabulin

- Nolatrexed

- Niraparib

- Nintedanib

- MK-2206

- Methyl Aminolevulinate

- Midostaurin

- Iniparib

- Infigratinib

- Ilorasertib

- Idelalisib

- Idasanutlin

- Galunisertib

- Glufosfamide

- Galeterone

- Firtecan pegol

- Forodesine

- Fedratinib

- Evofosfamide

- Enobosarm

- Endoxifen

- Emivirine

- Dexanabinol

- Disomotide

- Dactolisib

- Darinaparsin

- Dabrafenib

- Immunological Agents

- Antifungals

- Metabolic Bone Disease

- Ophthalmic Agents

- Inhibitors/Agonists

- Protease

-

Metabolic Enzyme

- COMT

- CETP

- Cathepsin

- Carbonic Anhydrase

- ATP Citrate Lyase

- Aminopeptidase

- Aldose Reductase

- ALDH

- Adenosine Receptor

- Adenosine Kinase

- AhR

- Adenosine Deaminase

- ACE

- ACC

- 5 Alpha Reductase

- 15-PGDH

- Xanthine Oxidase

- VD/VDR

- Transferase

- Thrombin

- Thioredoxin

- SPHK

- SGK

- SCD

- ROR

- Renin

- RAR/RXR

- Phosphorylase

- Phospholipase

- PDHK

- PDE

- P450

- Mineralocorticoid Receptor

- NAMPT

- MAO

- LXR

- Lipoxygenase

- Lipase

- IDO

- IDH

- Hydroxylase

- HMGCR

- HIF

- Hexokinase

- GST

- GLUT1

- Glucokinase

- FXR

- Ferroptosis

- FAS

- Factor Xa

- FAAH

- Elastase

- DGAT

- DHFR

- Dehydrogenase

- Decarboxylase

- CPA

- MAPK/ERK Pathway

- JAK/STAT Signaling

-

GPCR/G Protein

- Cholecystokinin Receptor

- CaSR

- Cannabinoid Receptor

- cAMP

- Bradykinin Receptor

- Angiotensin Receptor

- Adenosine Receptor

- Vasopressin Receptor

- TSH Receptor

- RGS

- Ras

- PAR

- PAFR

- Prostaglandin Receptor

- P2Y Receptor

- OXTR

- OX Receptor

- Opioid Receptor

- NMUR

- Neurotensin Receptor

- Neuropeptide Y receptor

- Motilin Receptor

- LPL Receptor

- LPA Receptor

- Guanylate Cyclase

- GNRH Receptor

- Glucagon Receptor

- GHSR

- Endothelin Receptor

- Epigenetics

- Endocrinology/Hormones

- DNA Damage

- Cytoskeleton

- Cell Cycle

- Biochemical Reagents

- Immunology/Inflammation

- Autophagy

- Apoptosis

- Anti-infection

- Membrane Transporter/Ion Channel

- Protein Tyrosine Kinase/RTK

- Ubiquitin

- Stem Cells/Wnt

- Biochemical Reagent

- PI3K/Akt/mTOR

- Other Inhibitors

- Natural Products

- ADCs

- Chemistry

- Chemical Biology

- Stains and Dyes

- Specialty Synthesis

- Synthetic Reagents

- Asymmetric Synthesis

-

Catalysis Chemistry

- Diketone Ligands

- Cross-Coupling using Transition Metal Catalysts

- Cross-Coupling

- Carbon-Donor Ligands

- C-H Activation

- Transition Elements

- Photocatalysts

- Rare-Earth Elements

- Phosphorous Compounds

- Organocatalysts

- Olefin Metathesis

- Olefin Ligands

- Non-Precious Metal Catalysts

- Nitrogen-Donor Ligands

- Main-Group Elements

- Hydrogenation

- Metal Catalysts

-

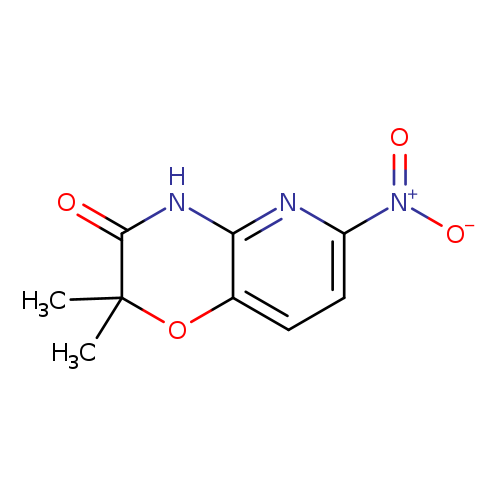

Heterocyclic Building Blocks

- Furans

- Epoxides

- Dioxoles

- Dioxolanes

- Cinnolines

- Carbazoles

- Benzoxazoles

- Benzothiophenes

- Benzothiazoles

- Benzofurans

- Benzodioxans

- Benzisoxazoles

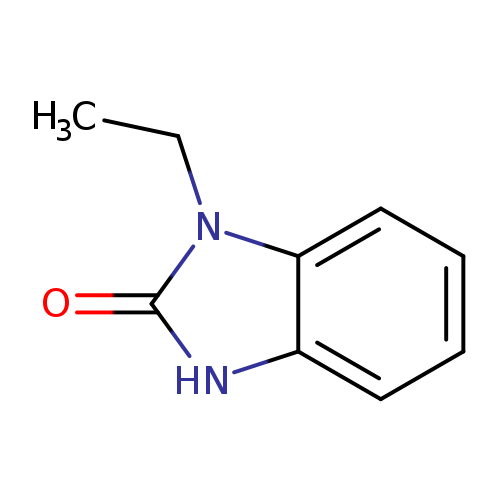

- Benzimidazoles

- Azetidines

- Acridines

- Triazoles

- Triazines

- Thiomorpholines

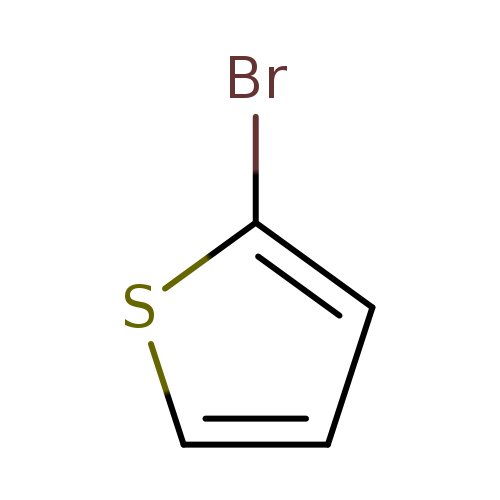

- Thiophenes

- Thiazolidines

- Thiazoles

- Thiazines

- Thiadiazoles

- Tetrazoles

- Tetrahydroquinolines

- Tetrahydropyrans

- Tetrahydroisoquinolines

- Tetrahydrofurans

- Spiroes

- Quinuclidines

- Quinoxalines

- Quinolines

- Quinazolines

- Pyrrolines

- Pyrroles

- Pyrrolidines

- Pyrimidines

- Pyridazines

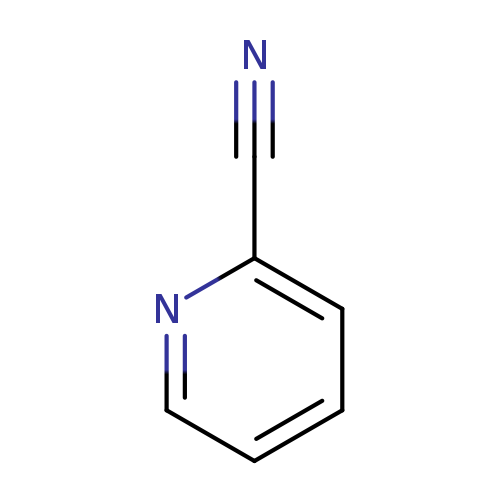

- Pyridines

- Pyrazoles

- Pyrans

- Pyrazines

- Purines

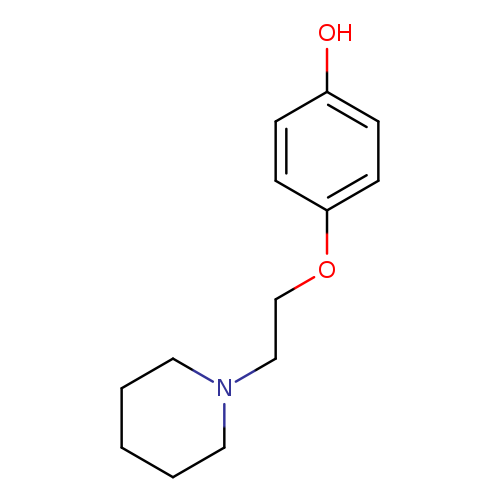

- Piperidines

- Piperazines

- Phthalazines

- Oxetanes

- Oxazolines

- Oxazolidines

- Oxazoles

- Oxazines

- Oxadiazoles

- Other Aromatic Heterocycles

- Naphthyridines

- Other Aliphatic Heterocycles

- Isothiazoles

- Isoxazoles

- Morpholines

- Isoquinolines

- Indolines

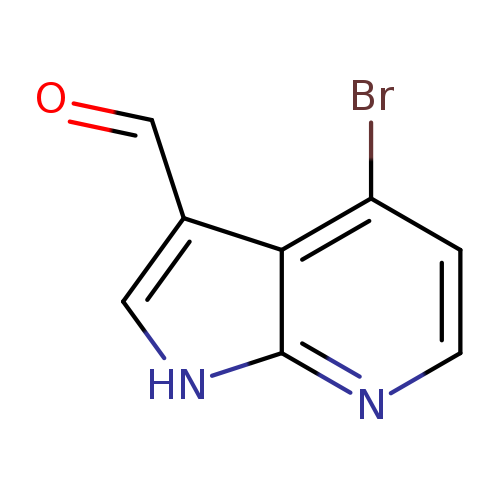

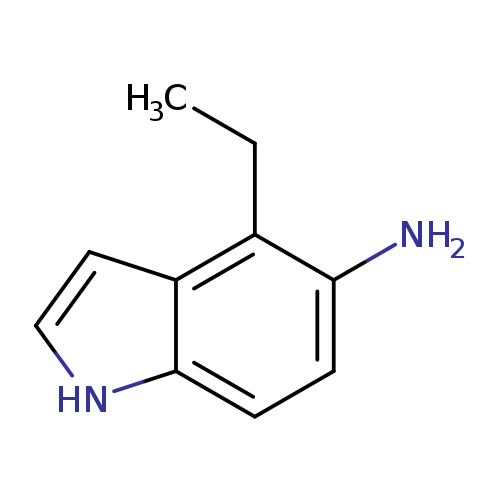

- Indoles

- Imidazolines

- Indazoles

- Imidazolidines

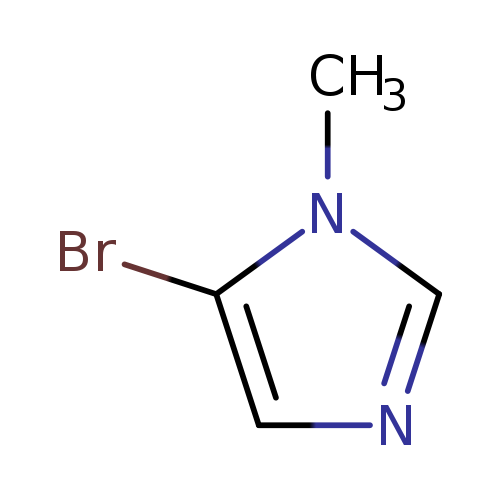

- Imidazoles

-

Organic Building Blocks

- Aryls

- Anhydrides

- Amines

- Amidines

- Amides

- Alkynyls

- Alkyls

- Alkenyls

- Aliphatic Cyclic Hydrocarbons

- Aliphatic Chain Hydrocarbons

- Aldehydes

- Acyl Chlorides

- Alcohols

- Ureas

- Trifluoromethyls

- Thioureas

- Thiophenols

- Thiols

- Thioesters

- Sulfoxides

- Sulfonyl Hydrazides

- Sulfonic Acids

- Sulfonyl Chlorides

- Sulfonates

- Sulfones

- Sulfides

- Sulfamides

- Phosphoruses

- Oximes

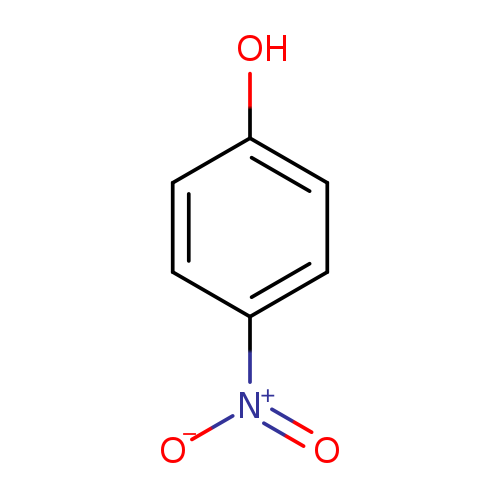

- Phenols

- Nitroes

- Nitrates and Nitrites

- Nitriles

- Ketones

- Isocyanides

- Isocyanates and Isothiocyanates

- Iodides

- Hydroxylamines

- Hydrazones

- Hydrazines

- Hydrazides

- Guanidines

- Fluorinated Building Blocks

- Ethers

- Esters

- Diazoes

- Difluoromethyls

- Chlorides

- Carboxylic Acid Salts

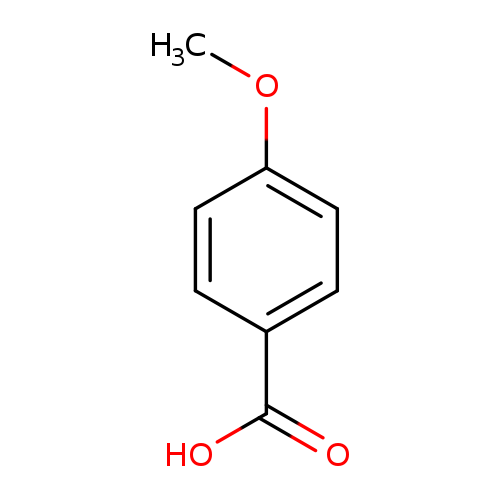

- Carboxylic Acids

- Bromides

- Benzyl Chlorides

- Azoes

- Benzyl bromides

- Organometallic Reagents

- SUPPORT

- RESOURCES

- ABOUT US

- CONTACT US